3D printing a mmWave antenna let’s you quickly build prototypes.

MIMO antennas, waveguides, traveling wave tubes, and RF substrates are fabricated using various 3D printing technologies. For example, 3D printing has been used to produce highly dense and integrated waveguide signal interconnects modules in a single monolithic unit. By printing the waveguide modules in one component, the part count was significantly reduced from tens or hundreds of parts, thereby optimizing weight and facilitating system integration.

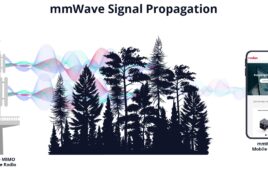

3D printed solutions are still under development but could significantly affect the cost/performance trade-offs of 5G systems, especially for 5G new radio millimeter-wave (mm-wave) applications. The front-end modules needed to support mm-wave systems cost more than systems operating at microwave frequencies. For example, critical passive components such as antennas and filters shrink at mm-wave frequencies and demand high-precision fabrication and assembly. That’s expensive and can be time-consuming. And cost-effective, low-loss interconnects, and packaging solutions will be required to minimize the loss of signal power and maintain signal integrity.

3D printed MIMO antennas for 28 GHz band

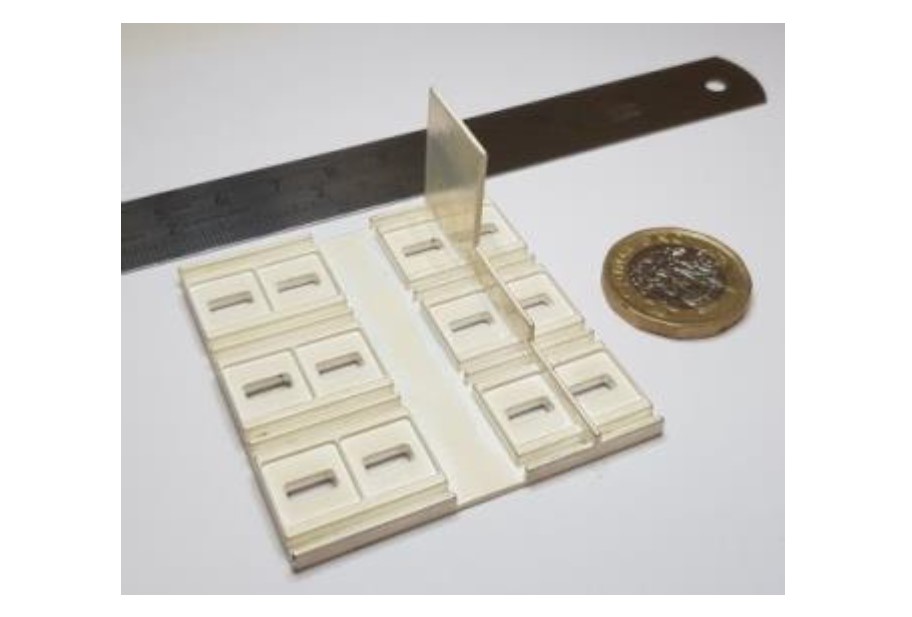

3D printing is being used to develop low-cost multiple input multiple output (MIMO) antennas for 5G and other mm-wave applications. The 3D printed 28 GHz MIMOs (Figure 1) have a bandwidth exceeding 4 GHz. They can deliver beams in multiple directions that provide continuous and real-time coverage in the elevation of up to ±30° without using phase shifters. The main beam direction of an element in the MIMO is steered over the entire bandwidth using 3D printed walls with different heights on the side of the 3D printed radiating antenna. In addition to changing the direction of the antenna’s beam, the wall can increase the gain of the individual antennas and the entire MIMO structure simultaneously over the entire bandwidth.

3D printed horn antennas for 28 GHz

Conventional horn antennas deliver high performance but can be expensive devices. The use of 3D printed high gain horn antennas, and waveguides may provide a cost-effective means of wirelessly linking a large number of small cells, micro base stations, and IoT devices that will be needed to provide millimeter-wave 5G on a massive scale.

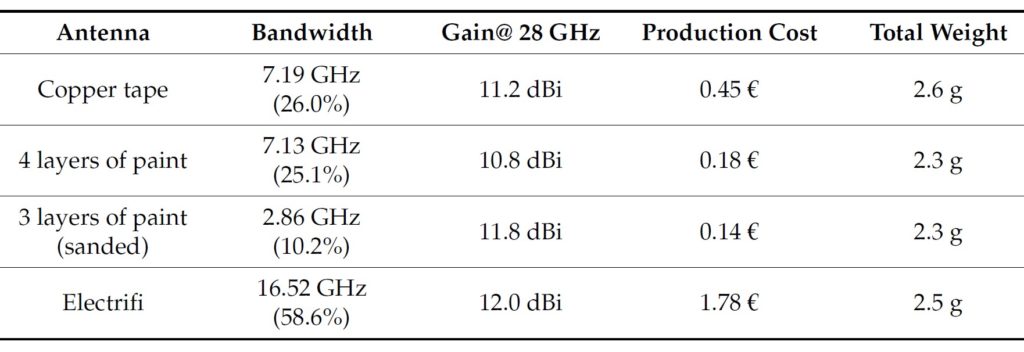

Several 3D printing approaches have been analyzed and compared with each other and with a conventional machined metal horn antenna. One study compared three ways to use 3D printing to fabricate 28 GHz pyramidal horn antennas. Two antennas were printed with non-metallic polylactic acid (PLA); one was covered with copper tape and the other with conductive spray paint. The third antenna was printed using a conductive filament. All three of the printed antennas combine good results with low production costs. The antenna printed with the conductive filament achieved a better gain than the other structures and delivered a wider bandwidth.

The performance of all three 3D printed horn antennas was good and could meet the requirements of the next generation of 5G devices. The production costs were estimated based on the quantities of the materials used in the fabrication of the antenna but did not consider the costs of the connector. The results confirmed that 3D printing would significantly reduce manufacturing costs compared with conventional horn antennas. Replacing the metal in the body of the antenna with PLA or the conductive filament also reduced the weight. A conventional metal horn antenna with similar performance would weigh at least 10-times more and be much more expensive.

The conductive filament is more expensive than PLA but also delivered superior performance. And since it is a solid structure instead of a copper foil wrapped or painted structure, it is expected to be more durable. There are other 5G and mm-wave applications that may benefit from using 3D printing using the conductive filament, including EMI/RF shielding, antennas, filters, and custom RF components.

Electrochemical additive manufacturing

Traditional metal 3D printers use laser-based technology. That results in high costs for both the printer and the metal powders that are used. Electrochemical additive manufacturing (ECAM) is an emerging area of metal 3D printing that eliminates metal powders and lasers. The resulting processes can produce precision metal parts such as antennas and travelling wave tubes that can be mass-produced at low cost. The electrolytes used by ECAM printers are as much as an order of magnitude less expensive compared with metal powders.

In addition, when using lasers to fuse metal powders into a solid structure, microvoids, rough surfaces, and thermal stressing must be considered. ECAM printing does not suffer from those issues since it builds up the metal component atom-by-atom and produces fully dense parts with very good surface finishes. This discussion reviews two different approaches to ECAM printing.

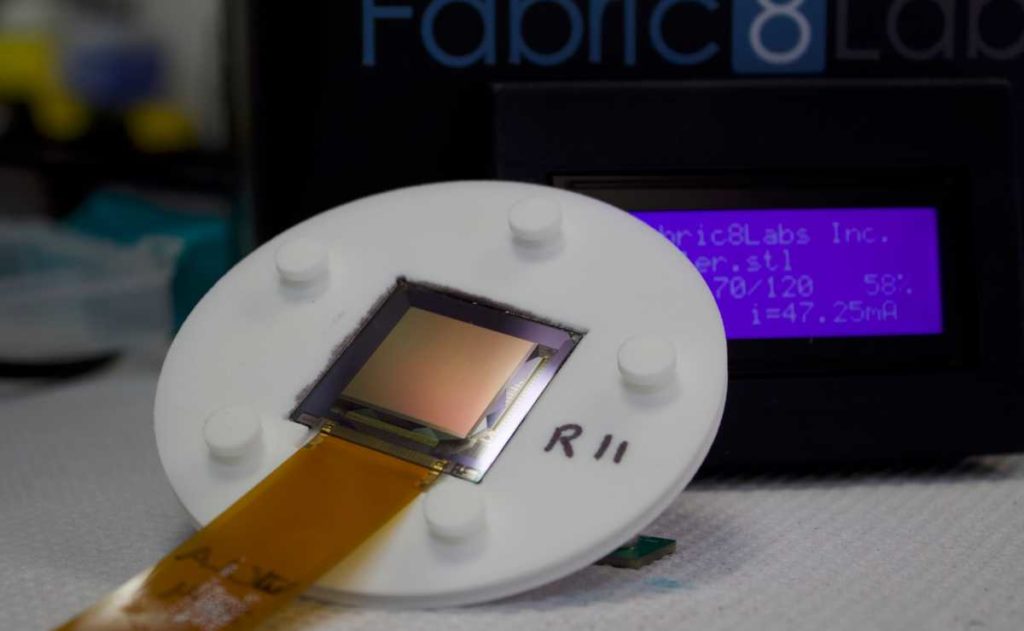

The first ECAM approach uses a print head that can print an entire layer at once. The printhead structure was adapted from thin film display technology (Figure 3), allowing for the first high-resolution 3D structures to be printed. Currently, the printhead, and therefore the printing area, is limited to 1 square inch (25 by 25 mm), but that will scale up as the technology progresses into printheads the size of a large monitor or television. That will allow the mass production of precision metal components and very large pieces.

Thin film printhead 3D printing technology deposits metal atoms at the speed of mass manufacturable industrial processes. The process leverages proven technologies developed from the LED industry to produce software-defined metal parts with ultra-high precision. In addition to increasing the printhead size, the next goal is to scale down the individual pixels from the micrometer scale to the nanometer scale, enabling ultra-high precision metal printing. That could be especially handy for 5G, where high frequencies and short wavelengths will deliver high bandwidth. Short wavelengths need tiny antennas and other structures such as travelling wave tubes (TWTs).

ECAM printed TWTs

The European Union’s Ultrawave project (“Ultra Capacity Wireless Layer beyond 100 GHz based on Millimeter-wave Travelling Wave Tubes”) has entered its second phase focusing on the production of waveguides in TWTs. A finite element modelling (FEM) analysis of waveguide shapes and their effect upon signal strength was conducted by the Goethe-Universität Frankfurt. Without waveguides, the RF energy expands into 3D space, and the signal is degraded.

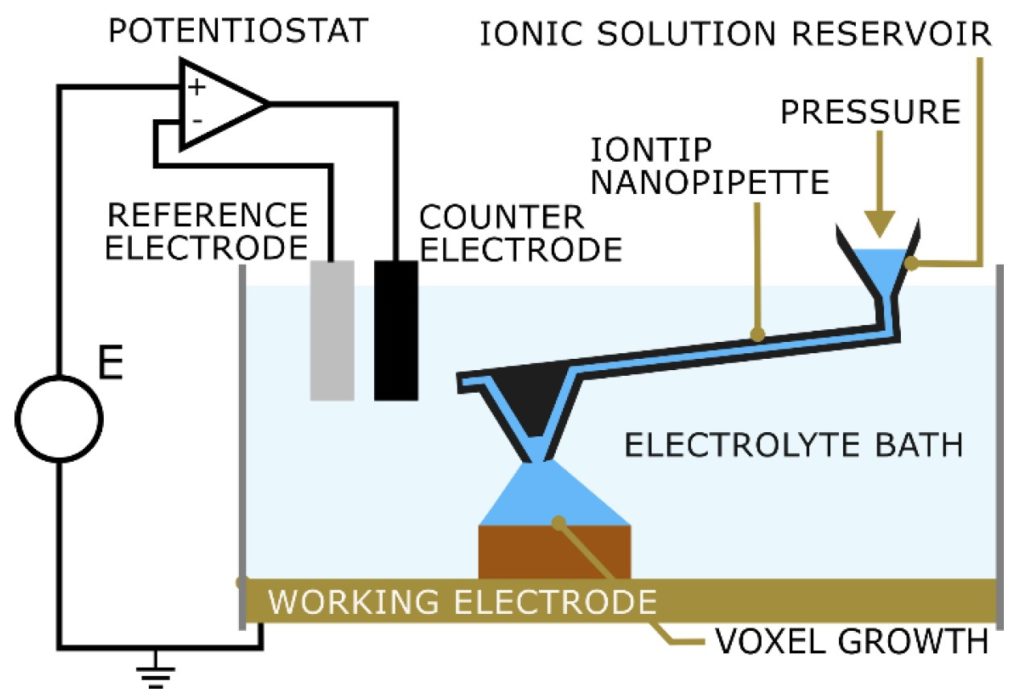

Measuring about 120 µm in diameter, tiny waveguides printed out of pure copper can eliminate that signal degradation. In this case, a small printing nozzle, called an iontip, is immersed in an electrolyte bath. A precisely regulated air pressure pushes a liquid containing metal ions through a microchannel inside the iontip. The liquid flow can be as low as femtoliters per second. At the end of the microchannel, the ion-containing liquid is released onto the print surface. The dissolved metal ions are electrodeposited as solid metal atoms.

The metal atoms are used to build small voxels, the 3D printing equivalent of a pixel in imaging. The use of smaller voxels enables the printing of smaller feature sizes (Figure 4). The forces acting on the iontip are optically measured, and the resulting feedback provides real-time process control of the printing. The optical feedback also enables the system to detect which voxels of the object have already been printed.

This high-precision electrochemical printing process takes place at room temperature. The resulting metal structures can be used immediately; there is no cooling or other post-processing required.

Summary

As shown, there are various possible applications for 3D printing in 5G and mm-wave systems. New printing techniques and new printing materials are developing that aim to revolutionize the fabrication of precision high-frequency RF components. In some cases, these new 3D printed components could out-perform conventional devices, and at the same time, cost much less and be lighter weight. 3D printing is being developed for a wide variety of electronics beyond 5G systems. Check out “3D and 4D printed electronics” and “Advanced power electronics packaging” for more info.

References

Metal 3D Printing with Submicron Resolution, Exaddon

A Fully 3D Printed Multi-Chip Module with an On-Package Enhanced Dielectric Lens for mm-Wave Applications Using Multimaterial Stereolithography, IEEE

mm-Wave Low Cost 3D Printed MIMO Antennas with Beam Switching Capabilities for 5G Communication Systems, Cornell University and IEEE

No heat, no laser, no powder: Fabric8Labs reinvents 3D-metal printing, Imec

The Use of 3D Printing Technology for Manufacturing Metal Antennas in the 5G/IoT Context, MDPI

Ultrawave project, European Union

This article originally appeared in Analog IC Tips.

Tell Us What You Think!