5G’s antennas and the devices that drive them generate more heat than their LTE predecessors. That creates new cooling problems for wireless devices and systems.

If you listen to and read the hype surrounding 5G, you’ll come away thinking that 5G is truly hot. That’s the marketing perspective. From an engineering design perspective, 5G is also hot. Indeed, it’s hotter than LTE in terms of the heat dissipated by the electronics because of the multiple antennas. If you’re designing 5G into a router or other fixed-access device, you will encounter thermal issues to a greater “degree” than in products that use LTE for wireless communications, even though the energy-per-bit might be less than LTE because of 5G’s greater bandwidth.

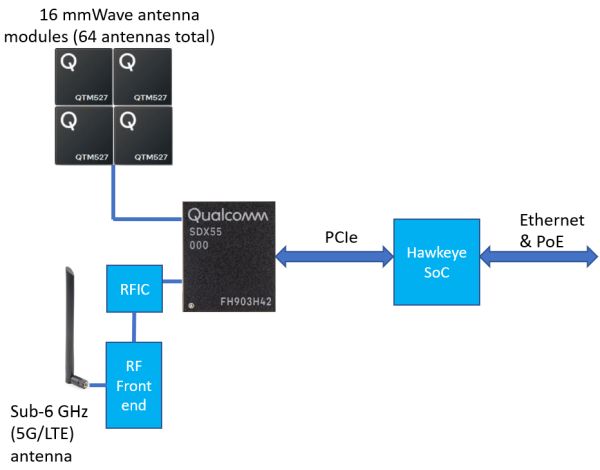

5G Technology World spoke with engineers at Cradlepoint and Sierra Wireless, both of whom have had to overcome heating issues. Both use Qualcomm’s Snapdragon X55 5G modem and antenna modules in their products. The thermal issues result from the physics of 5G, particularly with mmWave frequencies. 5GTW also spoke with an engineer at Laird Performance Materials, a manufacturer of thermal interface material (TIM) and EMI shielding products, who explained that 5G is raising heating issues not seen previous cellular designs.

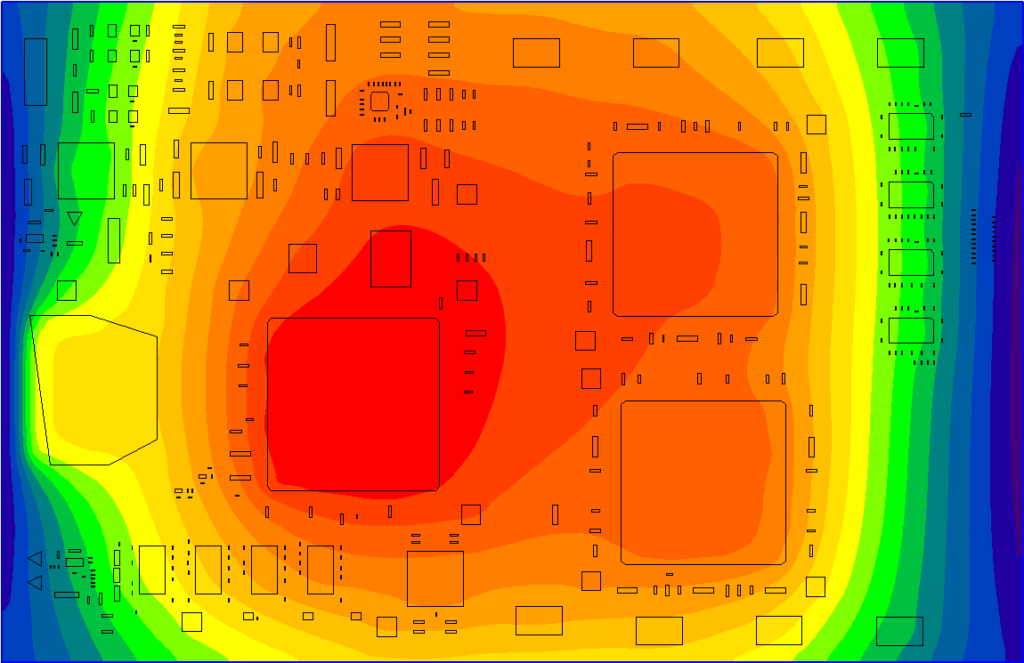

Cradlepoint’s Roger Billings told 5GTW that when designing its W2000-Series 5G Wideband Adapter (Figure 1), engineers modeled the system’s thermal characteristics and found the need to use heat pipes and fins to cool some components. Fig. 1 shows the fins used as part of the product’s thermal management. The case uses some 8 kg of aluminum to keep the inside cool. In addition, Cradlepoint uses a white case—as opposed to other products in black—to help with cooling. The W2000 is powered using Power Over Ethernet (PoE) according to IEEE 802.bt specifications. The adapter is often used outdoors. Figure 2 shows an example of how heat from a hot IC can spread to affect other components.

Figure 2. A thermal simulation shows how heat from one component can spread to affect others. Image: Mentor Graphics.

Figure 3 shows how Cradlepoint uses the X55 in conjunction with Qualcomm extended range mmWave antenna modules. The modules contain the RF signal chain—amplifiers, filters, mixers, beamforming—and each contains four antennas. The Cradlepoint W2000 uses a total of 64 antenna elements (4x4x4). The antennas and the electronics to drive them come with a price: heat. Hence, the heat pipes.

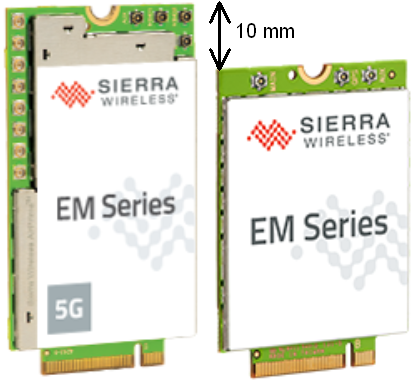

Sierra Wireless also uses the X55 and Qualcomm antenna modules in its EM9190 series 5G modules (Figure 4). Sierra’s Larry Zibrik explained that dissipating the 15 W to 16 W generated by the 5G modem and antenna required a new module design. As Fig. 3 shows, engineers had to increase the module size from 42 mm to 52 mm to accommodate 5G cooling. “Designing 5G into modules and IoT devices used in permanent installations is different than designing handsets,” said Zibrik. The transmit power is higher and with it comes power supply and heating problems.”

Figure 4. Sierra wireless extended its wireless module by 10 mm to accommodate heating of 5G components. Image: Sierra Wireless.

Adding the antennas and supporting electronics not only creates cooling issues, it can also creates EMI problems. That’s the takeaway from Jason Strader, Director of Technology, Product Development at Laird.

To attain enough thermal transfer from hot ICs to heat sinks or liquid-cooling materials, you need better heat transfer than you get with, say, copper-to-copper connections. That’s because of surface roughness. According to Strader, a typical copper-to-copper connection gets just 10% direct contact. Figure 5 shows TIM attaches to an IC package.

As in the Cradlepoint and Sierra Wireless applications, a typical 5G fixed-access application might have 64 antennas. At cellular frequencies below 6 GHz, a typical application has one-to-four external antennas (think your Wi-Fi router). A sub-6 GHz transmitter might consume just a few watts of power as opposed to the 15 W or so needed to drive the mmWave 64 antennas.

Figure 5. Thermal interface material provides better contact from ICs to heat sinks that is possible with direct contact. Image: Laird Performance Materials.

Strader also explained how 5G produces new EMI issues and their relation to thermal issues. “You’ll need a TIM to bridge the hotter ICs to cooling components.” But heat-dissipating components can themselves cause EMI problems if located too close to the antenna. If that’s the case, you may need to use a TIM that both conducts heat and absorbs RF energy. Try to get the antenna as far away from EMI-sensitive components as possible. One way to do that is to use as thick a TIM as possible, but make sure the material has enough thermal conductivity.

Always take a system-level approach to cooling and EMI issues. One can affect the other.

Have you seen heating/power issue with equipment that uses 5G? Are you waiting for 3GPP release 16, which will cover IoT, before making plans to design on 5G? Are you waiting for wider deployment?