Horticulture is one of the fastest expanding application sectors for LED lighting. It is a potentially huge market worldwide, encompassing large and small-scale commercial growers including specialist chambers, greenhouses and hydroponic installations. Greenhouse cultivation is becoming more important worldwide, as there is increased demand for specialist produce, year-round production, and continuing pressure to reduce the unnecessary transportation of fresh food by instead growing locally.

In Nordic countries, northern central Europe, Alaska and Canada, long periods of darkness in winter mean that there is a huge potential market for horticultural lighting systems to extend the growing season. In more temperate zones, lighting is just as important for enhancing natural sunlight as well as extending the growing season. In the Netherlands, for example, a significant percentage of this small country’s land mass is devoted to horticulture. Indeed, it is the world’s second largest exporter of agricultural products, after the USA. Together with the USA and France, the Netherlands is one of the world’s three leading producers of vegetables and fruit. It supplies one fourth of the vegetables exported from Europe. Dutch greenhouses are part of one of the most innovative sectors in the Netherlands, producing food extremely efficiently using sustainable energy. LED lighting, powered by windmills, forms an important part of that effort.

In other countries and regions, such as Japan, where there has always been limited traditional farming land, LED lighting is opening new opportunities for completely enclosed, indoor farms or plant factories that will boost domestic food production significantly.

There is an increasing emphasis worldwide on reducing energy consumption to reduce the carbon footprint: this, combined with increased electricity costs, has led to growing interest in energy efficient solutions, such as LED lighting systems. Light for growth Plants in a greenhouse environment need the correct temperature plus light to allow optimal energy absorption by chlorophyll, the primary pigment responsible for photosynthesis, and to stimulate plant growth. Academic research conducted over many years has proven that plants are more sensitive to particular wavelengths of light, primarily in the blue and red spectra.

Back in the late 1980s and early 1990s, when LEDs were barely commercially viable, research was already underway in both the US and The Netherlands, using red LEDs on their own and in conjunction with blue fluorescent lamps. The researchers had to wait several years for useful blue LEDs. Costs were high, building arrays for large-scale lighting was impractical, and the devices were difficult to fabricate consistently, which meant projects were limited. In the US, NASA investigated the use of LEDs in off-planet life support systems. In Holland, the primary goal was to create specialist chambers for seed germination and root cuttings.¹

Red + Blue = Green

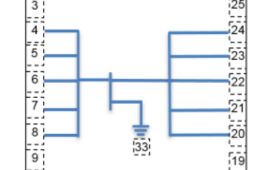

Meanwhile, more recent research and trials have confirmed that plants respond with increased chlorophyll absorption and photosynthesis when exposed to red (640 to 660 nm) and blue (450 nm) light sources. In particular, studies have shown that the light absorption spectral peaks for chlorophyll correspondingly fall within the ranges of 400 to 500 nm and 600 to 700 nm. (See Figure 1 below.) The 400 to 700 nm range is commonly referred to as the photosynthetically active radiation (PAR) range.

Figure 1: Research has shown plants respond best to light in the 450 nm and 660 nm ranges (Illustration source: Lumigrow, US manufacturer of horticultural lighting systems).

Technology advances

Since 2000, LED technology has advanced considerably. Devices are now available to cover a much wider color spectrum, and with a range of outputs. For lighting applications, high output devices are essential. Today, sufficiently high output LEDs can be manufactured economically and consistently in high volumes. These are suitable for a range of large-scale lighting applications. The construction of larger arrays and modules has also become economically feasible.

Digital and spectral control

One of the most significant advantages of LEDs is that they can be easily incorporated into digitally controlled and programmable systems. Arrays can be zoned and controlled separately, to suit successional sowing requirements, or different crops in the same greenhouse, for example. Complex programs can be set up and run automatically, allowing accurate simulation of sunrise/sunset events. LEDs can be brightened and dimmed gradually or used at very high output levels. They can be turned on and off instantly, as required.

Possibly one of the most important advantages of LEDs for horticultural lighting is that this is the first light source with the capability of true spectral composition control. The LEDs emission spectrum can be fine tuned to match the peak absorption wavelengths of chlorophyll, ensuring that the light output is much more effective in stimulating photosynthesis and plant growth, thereby enabling growers to optimize production and influence plant morphology and composition.

Research conducted in Asia, for example, has found that vegetables grown under LED lighting have softer leaf tissue compared to the same plants grown in the field. This makes them a popular choice for consumers. The researchers also determined that a 3:1 ratio of blue to red LEDs is the best combination for horticultural lighting in their specific application.

Other studies have shown that varying the spectral composition during the growing phase of plants (germination, root growth, leafing, fruiting, etc.) can be beneficial. Research also continues into which precise spectral composition is optimal for different plant types.

Control of the spectral composition of the LED arrays also leads to considerably improved energy efficiency. Conventional horticultural lighting systems have relied on metal halide and high-pressure sodium (HPS) technologies. HPS lamps have been the most commonly used light source for supplemental lighting in greenhouses. Researchers have compared the spectrum of HPS lamps with the chlorophyll absorption peaks, demonstrating that most of the light output from HPS lamps falls outside the peak absorption ranges of the chlorophyll. In fact, they found that only 7 percent of light created by HPS lamps is absorbed by plants. Therefore, most of the light created with these lamps is wasted, as is the energy used to create it.

Finally, spectral composition control can stimulate healthy plant growth in such a way that the use of fertilizers and other plant food can be significantly reduced or even eliminated, saving further costs and minimizing the use of chemicals. Experiments conducted in some countries have noted a reduction of up to 30 percent in the amount of fertilizers used, while others, particularly in Asia, have managed to eliminate the use of artificial fertilizers completely.

Simpler construction, energy saving

Additional advantages of LED lighting, as have been demonstrated in their use in other industrial and civic applications, are also appropriate to horticultural applications: lower energy consumption, compact fixture construction with fewer ancillary components, high output with little radiant heat, and longer life (10 times longer than HPS is a common claim), which in turn leads to reduced maintenance costs overall.

There are countless case studies showing that by converting from HPS to LED lighting, considerable energy savings can be achieved. Figures quoted range from 30 to 60 percent reductions in energy bills. In new-build applications, or on farms where existing infrastructure needs replacing, it appears that LED lighting has already become the solution of choice. In other installations, some lighting system manufacturers are now able to present the case that replacing HPS with LED technology will generate sufficient savings and boost yield revenues to ensure a return on investment in a relatively short time (one to two years). In some areas, governments are legislating to phase out the use of HPS technology.

Some horticultural lighting systems are constructed to take full advantage of LED technology so the need for ballasts is eliminated, cooling systems and venting can be minimized because less heat is generated, and reflectors are not required. Such systems are supplied with full digital control and programmability for easy installation and set up.

Fixture flexibility

Continued developments exploiting solid-state lighting technology in fixtures and systems have led to completely new approaches to horticultural lighting solutions. This has been largely achievable due to the fact that even very high output LED systems, when appropriately assembled, benefit from reduced radiant heat. This means lights can be located much closer to plants without causing any heat damage. Instead of standard overhead strings of lights, modern greenhouses are now using layering techniques and intra-canopy configurations. Low profile LED strips for shelf lighting are ideal for seedlings, for example, enabling growers to install more shelves per greenhouse, while ensuring consistent light and temperature. Planar and vertical arrays of LEDs, typically configured as rails or bars, can be installed to best suit the plant type, as well as the size of the greenhouse and density of the plant canopy.

Buying in volume

It is only in recent years that LEDS suitable for horticultural applications, in terms of wavelength and sufficiently high light output, have become available at a price point that makes large arrays feasible. Leading US horticultural lighting manufacturer, LumiGrow, for example, offers an array incorporating 58 LEDs sufficient for a 1.5 square meter area. Commercial greenhouse installations can be measured in hectares!

Taking a look at the Digi-Key website, many leading LED manufacturers offer red and blue LEDs in the optimum PAR range (400 to 700 nm) required for horticultural lighting applications. Among them, both OSRAM Opto Semiconductors and Everlight Electronics are focusing on solutions for this market sector.

OSRAM has made significant advances, currently offering several ranges of LEDs aimed directly at horticultural lighting applications.

Figure 2: OSRAM Opto Semiconductor LEDs are used widely for horticultural lighting (Photo source: OSRAM Opto Semiconductor).

OSRAM’s TopLED LEDs are used by the million in horticultural lighting systems deployed in Finland greenhouses alone. In some cases, as shown in Figure 2, they are designed and installed in a curtain structure of 10 strips, each 25 m in length. By operating at the optimum wavelengths and intensity, these lighting installations are expected to achieve up to 60 percent energy savings over the traditional HPS lamps they replace. In addition, the curtain structure is also claimed to reduce light pollution, which is an issue in high-density population areas in northern territories.

Information from Digi-Key on red TopLED devices, with a 625 nm wavelength, 46 lm/W output and 120° viewing angle can be found here. For the equivalent devices in blue, at 470 nm wavelength, 10 lm/W output and 120° viewing angle, further information on sample availability and technical specifications can be found here.

Another range of interest for growing applications is OSRAM’s Golden Dragon Plus red LED devices, which combine red (625 nm), amber (617 nm) and yellow (590 nm) elements to give an optical efficiency of 59 lm/W, 67 lm/W and 53 lm/W respectively. With a viewing angle of 170°, these devices provide a highly efficient light source in a low profile package. Sample information and datasheet can be found here.

The complementary Golden Dragon Plus blue LED combines deep blue (455 nm), blue (467 nm), and true green (528 nm) elements to give optical efficiencies of 54 lm/W, 35 lm/W and 136 lm/W respectively. Sample information and datasheet can be found here.

Everlight, meanwhile, has both red and blue high output LEDs available through Digi-Key. It also offers ready-made fixtures, including modules, strip lights and arrays, incorporating its own LEDs, to the horticultural lighting sector. The literature available on the company’s website charts the relative luminous intensity across the spectrum of its 9:1 and 8:2 red:blue LED ratio combinations.

Figure 3: GL-Flora series of greenhouse shelf lighting fixtures from Everlight (Photo source: Everlight Electronics).

For those systems specialists and OEMs wanting to design and build their own fixtures, several series of Everlight LED components are available from Digi-Key. A case in point is the SHWO family.

A typical red device in this range features a 68 lm/W output and 120° viewing angle. More information on samples and datasheet can be found here. A typical SHWO 1 W range in blue has a 15 lm/W output, 465 nm wavelength, and 120° viewing angle.

A technology to watch

For the future, a new lighting technology is emerging. Light Emitting Plasma (LEP) is beginning to make inroads in the street lighting market, claiming advantages even over LED technology, in terms of exceptional color quality and higher brightness. Greater energy savings are partly due to the fact that LEP lights can be dimmed down to 20 percent of full brightness. Reliability is on par with LEDs, as is lifetime. LEP is claimed to provide better color rendering and light quality, which will appeal to other lighting market sectors such as cinematography and photography.

Horticulture is also a target application for this technology. LEP lamps generate light with a continuous color spectrum. A comparison of the spectral power distribution of natural daylight and LEP lamps shows that, except for very small drop-outs at approximately 425 nm and again at 475 nm, the light output of LEP lamps is almost identical to natural daylight.

In Europe, Gavita Nederland BV, a leader in horticultural lighting, has incorporated LEP technology from US company Luxim. Gavita recently launched a full-spectrum luminaire called GAN LEP, specifically designed for plant growing in sunlight-free rooms.

Another advantage of LEP technology, particularly for high brightness applications, is that the lumen density is considerably higher than that of LEDs. One manufacturer claims it can take around 100 typical high lumen LEDs to produce a comparable lumen output to a single plasma source. Another states that LEPs can produce 144 lm/W compared to 65 to 85 lm/W for LEDs in practical applications.

We have already seen that LEDs generate less heat than conventional metal halide (HMI) or HPS technologies. LEPs with a lower component count can generate even less heat than LEDs, can fit in a more compact fixture and ultimately may be a lower cost solution than LEDs for the same lumen output. LEDs, however, have the advantage of instantaneous turn-on.

How LEPs work

LEP bulbs can be regarded as tiny discharge lamps. However, unlike HMI bulbs, they do not have electrodes. Instead of applying a voltage and drawing a current through the lamp to create light as does an HMI, the energy that creates light in an LEP comes via a high frequency RF transmitter. The RF waves heat a ‘puck,’ which contains a sealed quartz bulb, bringing the materials inside the lamp to a plasma state. A highly reflective powder behind the lamp reflects a “flicker-free” light in a forward direction.

Conclusion

In the fast expanding horticultural lighting market, LED lighting is robust, long lasting, energy efficient and provides a more natural light output than traditional high intensity discharge technologies such as HPS or metal halide. While energy saving is, on its own, a significant motivation for replacing existing systems, the ability to control the spectral composition of an LED lighting system provides a compelling argument for change. The selection of the appropriate combination of red and blue LEDs, operating at the right wavelengths, has been proven to stimulate plant growth, thereby improving quality, increasing yields, and reducing the need for fertilizers. The reduced energy consumption, easy installation, flexible fixture options and simple digital control features of LED lighting allow growers to increase productivity, extend the growing season and reduce costs. As LED technology continues to advance, we can expect to see plenty of opportunities for innovation in this ‘growing’ market sector.

Article provided by Digi-Key Corporation, Tech Zone.

Posted by Sara Cohen, Editorial Intern

July 3, 2012