Since their inception, RFID (radio frequency identification) tags have largely been a highly useful but overlooked tool across various industries like manufacturing. Until recently, companies are beginning to realize the benefits of RFID, like its longer range and robustness. Implementation of RFID technologies in this particular industry has steadily increased, with manufacturers like automotive companies successfully experimenting, with RFID to track newly assembled vehicles through outbound preparation and shipping at several factories worldwide. This saves time on instances like the drivers of these vehicles not having to physically leave the vehicle to get paperwork stamped or verified, among others.

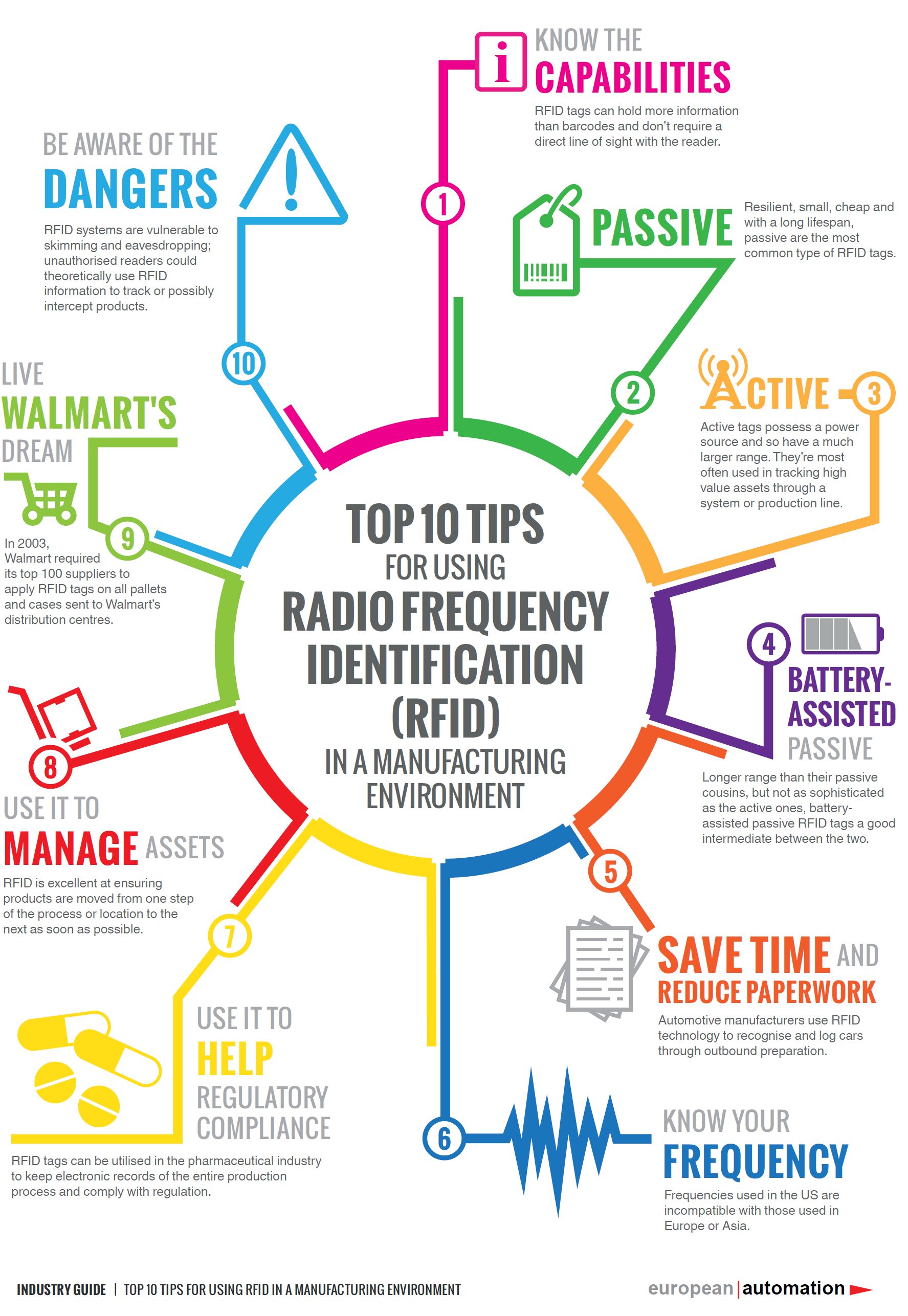

With RFID technology finally having a growing influence on manufacturing, there will be adjustments industry entities and technologists have to make on their daily operations, manufacturing methods, and handling of products that will improve and alter how these companies manage their assets and goods. Provided by European Automation, the infographic below features 10 tips for using RFID technology in a manufacturing environment.

(Image Credit: European Automation)