Engineers must consider these design tradeoffs when choosing data storage for embedded, IoT, and network equipment. 5G’s higher data rates adds another factor to the mix.

Connectivity without data storage is useless unless you’re simply making a voice call. Connected IoT devices make measurements from vehicles, connected machines, and the environment that must be captured stored, and analyzed for people and machines to make informed decisions.

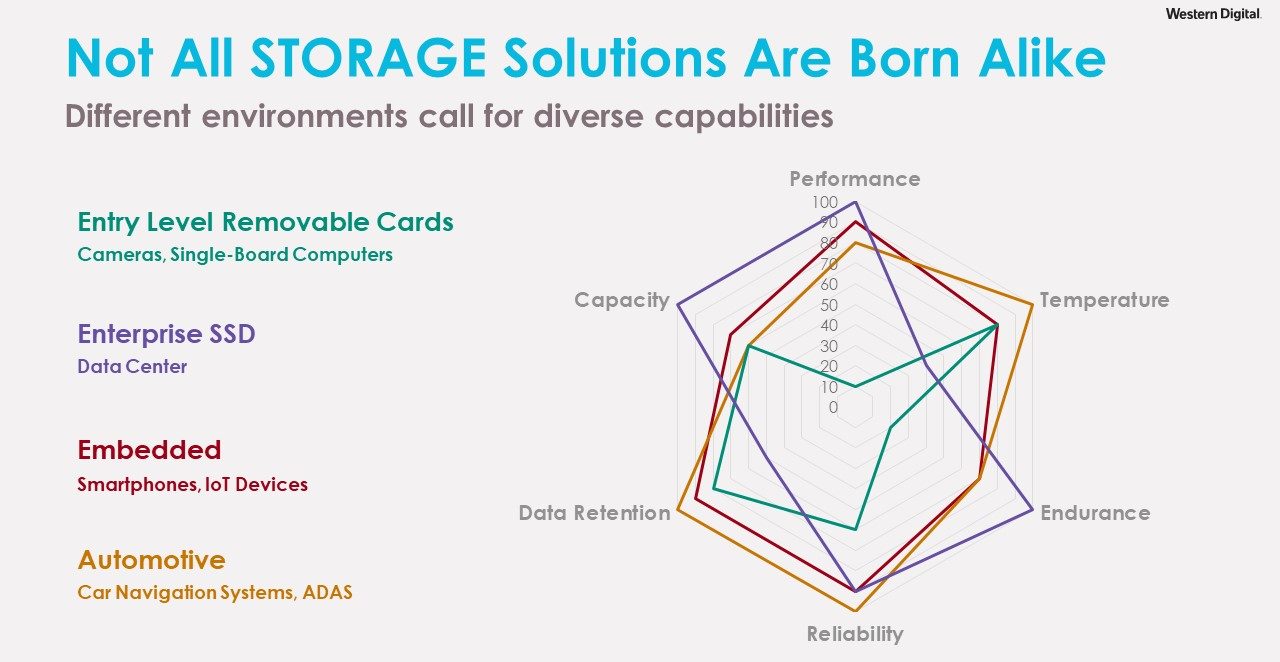

Applications drive storage design decisions, and those applications also drive a storage device’s internal design. What’s important in your application, endurance, read/write speed, data retention, or temperature?

5G Technology World spoke with Adi Klein, system architect and Yaniv Iarovici, director, IOT and edge segment marketing at Western Digital to discuss design considerations for adding storage to your device.

5GTW: What storage considerations must engineers consider when designing IoT or other devices?

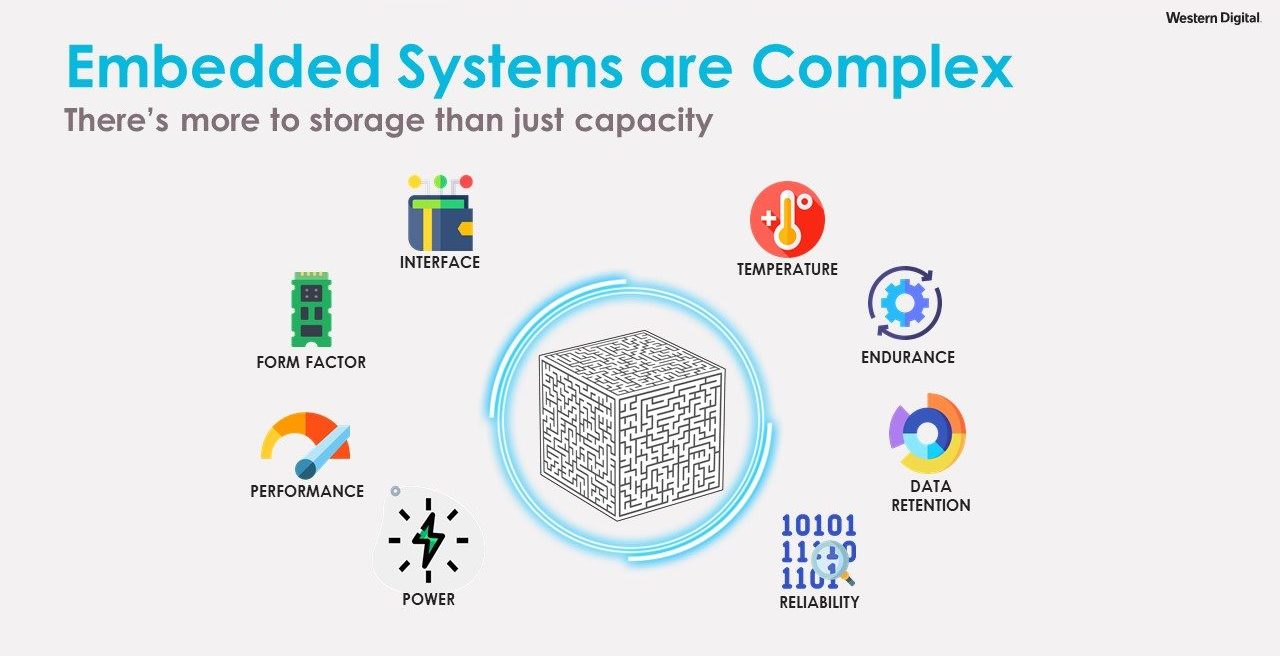

Klein: Engineers designing devices and systems that need storage (as opposed to memory) have several factors to consider (Figure 1). Interface bus options and form factors are among them.

Interface buses include Universal Flash Storage (UFS), Embedded Multi-Media Controller (eMMC), and SD cards. Non-Volatile Memory Express (NVMe) is still not used for IoT devices, but it could go there as well.

You must consider form factor, performance, temperature conditions, reliability, endurance, and data retention.

Endurance means how much data you can write to a storage device before it fails. Data retention means how long the memory device can be turned off and at what temperature you can still read the data.

Reliability is different than endurance. In an automotive application, for example, you don’t want the storage device to ever fail.

Yaniv Iarovici

Iarovici: No two designs are the same. Think of it as trying to solve an equation with multiple variables. Each design will have its own characteristics and requirements that dictate the storage selection. That’s similar to the process of selecting any component.

Klein: The next slide (Figure 2) compares the considerations in the previous slide. Looking at Entry Level Removable cards shows that performance and endurance needs are lower than for other applications, but temperature requirements are as high as for Embedded systems. Looking at Enterprise SSD, you see that it must store large quantities of data and have high endurance to avoid frequent drive replacements, but temperature needs are less important in data centers’ controlled environment.

Figure 2. Engineers must consider the tradeoffs when choosing a storage technology, starting with the intended application of your final product.

The needs for embedded systems fall somewhere in the middle. You need high performance but moderate endurance to ensure the desired product lifetime, say three to five years. Reliability and temperature range are important, though not as much as in an automotive application.

IoT covers a wide range of applications. It can be for a smart speaker at home or for virtual reality. Storage requirements vary widely. One application may need just 8 GB for an operating system and one application program. Others may need to store large amounts of data, say for gaming videos.

5GTW: How does designing for 5G connectivity change requirements as opposed to LTE?

Klein: 5G lets you download data at hundreds of megabytes per second. Your device must be able to store data coming in at that speed. Otherwise, you’re not taking advantage of 5G’s data rates.

Adi Klein

If you look at eMMC, a popular embedded storage bus, you can get about 300 MB/sec data rates for read, with lower write speeds. That’s good enough for 4G, but 5G requires data rates of 500 MB/sec. SD card storage data rates are about 100 MB/sec. That’s not even fast enough for 4G. You need a device that’s capable of writing at the speeds you need depending on connectivity technology you’re using. You need to move the bottleneck to some other part of the system.

Iarovici: In addition to having 5G connectivity, applications need ever more computing power. Looking at things from a system level, 5G also affects the chipsets that devices need. Today’s chipsets offer more storage flexibility than did their predecessors. IoT design from several years ago didn’t need the kind of computing power and storage that’s needed today. Today’s more advanced IoT system can use eMMC, UFS, and even SSD technology. Today’s chipsets pack more computing power and the support a variety of storage devices.

5GTW: How does memory management play a role in storage design?

Klein: Capacity is managed by the number of bits per cell where billions of cells reside in the same NAND die, and there are several dies in a product. There are, however, tradeoffs among performance/power, write endurance, and data retention. For example, writing to a cell faster can affect its ability to retain the data. Therefore, we have to tailor storage devices to applications. Take the case of a video camera. It’s writing lots of data all the time. We might maximize performance and endurance at the expense of data retention. When your product overwrites surveillance videos in a week, you don’t need ability to view them two years later. We make that adjustment on the NAND itself. We have a control layer and algorithms to make those kinds of adjustments. We also control wear leveling, which maximizes product endurance.

We need strong error correction codes (ECC) and low-density parity check (LDPC). NAND memory will have bit errors and we need to correct them, preventing the user from seeing a wrong bit. We must provide a means for preventing errors that result from degradation ever reaching the end user. These are the ways we account for the tradeoffs in Figure 2 that arise.

5GTW: Please explain how writing time affects retention length.

Klein: Let’s look at multi-level cell (MLC) in Figure 3. We know the capacity of the cell to store electrons. How accurately can we detect the different levels to correctly interpret bits? In this case, you have two bits per cell. Thus, we need four unique distributions to represent the four possible pairs of two bits. If we maximize the time to analyze that cell, we reduce its performance. Electrons shift over time. Thus, the distribution widens over time. If you start with a narrow distribution, you have more time before electrons change cells to the point where you can’t accurately detect a bit. This is the tradeoff between performance and data retention.

If you perform many writes to a cell, you reduce its performance than if you simply perform fast reads and writes before moving to another cell.

Iarovici: It’s a balancing act. A device must revisit cells from time to time according to a certain logic. It must make sure that the data is sustained over a long period of time. It’s not just a one-off event between writing speed and retention. We can achieve higher levels of reliability over time.

Klein: A device will adjust electron levels in a refresh operation when error rate increases, but only when the power is on. Data retention is a specification of how long a cell can retain its state when powered off.

5GTW: Please give us an overview of the common communications buses used with storage devices.

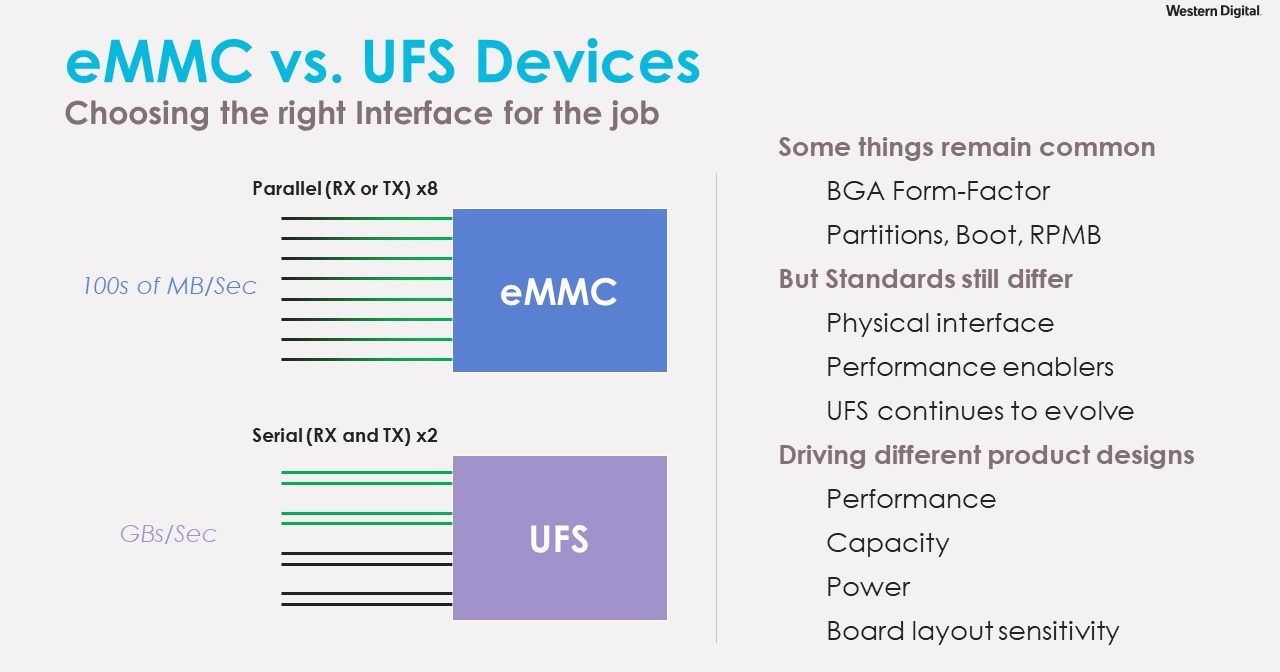

Klein: Both eMMC and UFS (Figure 4) come from JEDEC standards, but UFS had taken over.

Figure 4. The older eMMC interface uses a parallel architecture as where the UFS interface is a serial bus.

eMMC is a parallel interface that has eight parallel lines running on a 200-MHz clock. Bus width can get up to 400 MB/sec of data though data speeds around 300 MB/sec are typical.

UFS is a serial link that’s like PCIe at the PHY level. The UFS PHY was designed for mobile devices invented and by MIPI. It consists of four sets of lines, two for Tx (write) and two for Rx (read). Because we have separate lines, a controller can both read and write to memory at the same time. Today, UFS 3.1 has a data rate of 2 GB/sec. UFS 2.1 ran at 1 GB/sec and UFS 4.0 will run at 4 GB/sec. As you can see (Figure 4), eMMC and UFS share several characteristics. From a package point of view, both controllers are ball-grid array (BGA) devices. The ball mapping is different, but the chips look the same. You can partition the memory and boot a system with either bus.

There are, however, differences. With UFS, there are some performance enablers that go beyond eMMC. For example, commands can execute in parallel. The protocol enables that.

UFS is still evolving as where eMMC is not. We’re now at UFS version 3.1. You can find UFS 3.1 in mobile phones and IoT devices. UFS 4.0 is now being standardized and we should see products in 2023.

Prior to UFS 3.1, storage devices couldn’t achieve the 500 MB/sec write performance needed for 5G. JEDEC added a feature called “write booster” where the host can tell the device “I want you to take a load of data and write it into a single-level cell (SLC) non-volatile cache to increase write speed.” SLC has a higher threshold voltage than MLC and TLC in Figure 4. It’s a new API just to enable 5G.

5GTW: Are there capacity differences between eMMC and UFS-based storage devices?

Klein: While you can find eMMC devices from 8 GB up to 256 GB, UFS 3.1 starts at 32 GB and will soon reach a terabyte.

UFS is designed for using high speed serial interface. Signal integrity issues come into play. That make designing board layouts for UFS more challenging than for eMMC. Noise on the clocks and data lines must remain low.

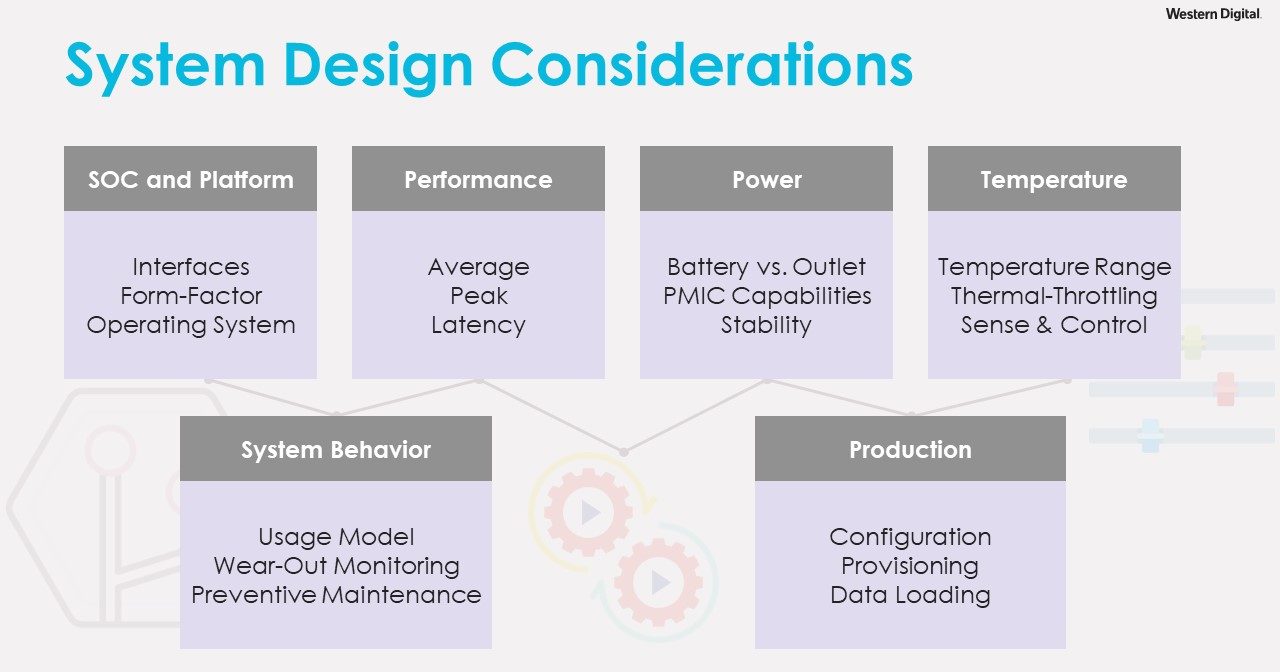

5GTW: What should system designers consider when choosing a storage technology?

Klein: First, you must see which interface your design can use. Older SoC’s still support eMMC and may not support the newer UFS bus. New devices may support UFS only.

For performance (Figure 5), you must understand your actual needs. That is, the read/write speeds, especially peak speeds. What happens if your system can’t maintain peak data rates? Can RAM or a network buffer the data?

For power, will your device run on batteries or be line powered? Power delivery must be sufficient to maintain peak data rates.

In what temperature range must your product operate? Will you include thermal throttling if the temperature gets too hot? Do you need to use fans to keep your device cool?

Engineers who don’t come from the storage world may not understand system behavior. You must think about monitoring the memory for wear out. Don’t assume that you can write data over and over and expect it to be there forever. Will the data be sequential or fragmented? What’s the expected lifetime of the product? Recent automotive recalls have occurred because eMMC devices failed. The designers didn’t anticipate the amount of data writing that would take place. eMMC and UFS both support monitoring and you can read that data.

Regarding production, you need to know how your device will be manufactured. Will the memory be partitioned? You need to make sure that your SoC supports provisioning if needed. Will you load the data before or after soldering the memory onto a board?

5GTW: With so many flash-memory devices manufactured and in use today, is the spinning hard drive dead?

Iarovici: Hard drives are very much alive, and growing, but address other use cases. Flash memory provides flexibility for low-power or on-the-move devices. If you think about the wide net of IoT, data is created at endpoints but may be stored in large datacenters. Hard drives still have significant use on those datacenters.

Klein: The amount of content and data that people and machines create is larger than the manufacturing capacity of all flash-memory vendors combined. We need spinning hard drives to hold all of those videos.

Tell Us What You Think!